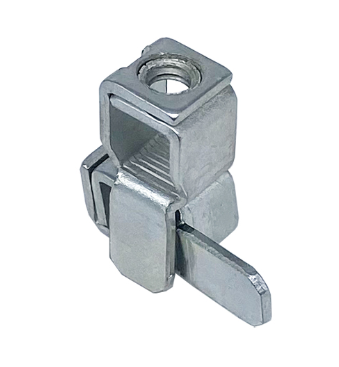

Cause of heating and burning of cage terminal

Cage terminal has the characteristics of high shock resistance, short wiring time, coupled with its heat resistance, corrosion resistance, is widely used in the field of electrical connection in the world. However, there are also some problems in the actual use of cage spring terminal, terminal burning failure often occurs, the main phenomenon is terminal burning, melting and so on. The following is a specific analysis of the heating causes of cage terminals.

1. The length of the wire in the pressing terminal does not meet the specified requirements

Cage wiring terminals have strict requirements on the length of crimped wires. The cross-sectional area of crimp conductors varies according to the requirements. For example, the allowable crimp area of a wiring terminal is 6 to 35mm2. Therefore, when the wire is too thin, because the pressure into the wire is too long, and the wire and the contact area has an insulating layer, resulting in the deterioration of the conductive capacity of the wire, so as to burn the terminal. For example, when the spring terminal is 285-635 and the main line of the power supply is 16mm2, a similar situation has occurred and the risk is extremely high.

2. The strip length of the wire inserted into the wiring terminal does not meet the requirements

Cage type spring terminal is also strict on stripping requirements. For example, the wiring length of the wiring terminal of the model 281-681 is 9 ~ 10mm. Too short stripping line will make the spring crimping area is too small, easy to cause obvious shedding. For stripping, not only must have rich experience, but also must be equipped with special stripping tools to fix the length of stripping.

Three, the cross-sectional area of the wire inserted into the wiring terminal does not meet the requirements

Cage spring terminals have strict requirements on the cross-sectional area of the crimped wire. If the cross-sectional area exceeds the required range, the wiring end of the wire cannot be fully inserted into the wiring terminal hole, resulting in decreased conductivity and hidden security risks. On a railway passenger car, the number of wires is often more, when the number of cage terminals is less than the required wire pressure, it is never allowed to screw two wires together and insert them into a terminal jack.

Four, cage type terminal accessories selection is improper

There are many accessories attached to cage terminal, such as block, short plate and adjacent jumper, and corresponding to the spring terminal model, for example, model 281-402 adjacent jumper can be used on 281 series terminals, can also be used in the case of insertion is not in place, but due to insufficient load, It is easy to cause terminal burning when working at full load.