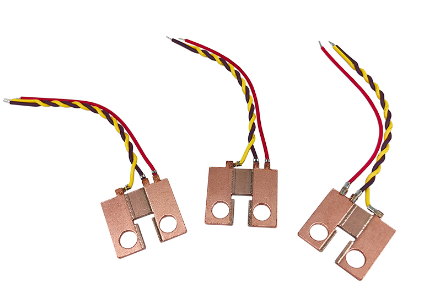

Thermal Effects and Temperature Drift of Current Shunt Resistors

In the field of electrical engineering, Current Shunt Resistors are widely used for accurate current measurements. However, it is important to consider the thermal effects and temperature drift characteristics of these resistors to ensure their reliable performance. This article aims to explore the impact of thermal effects and temperature drift on Current Shunt Resistors and discuss strategies to mitigate their influence.

1. Thermal Effects on Current Shunt Resistors:

When current flows through a Current Shunt Resistor, it generates heat due to power dissipation. This heat can lead to thermal effects, causing changes in the resistance value of the resistor. These thermal effects can significantly impact the accuracy of current measurements. It is crucial to understand and quantify these effects to ensure precise and reliable current measurements.

2. Temperature Drift Characteristics:

Temperature drift refers to the change in resistance value with variations in temperature. Current Shunt Resistors are typically made of metal or metal alloys, which exhibit temperature coefficients of resistance (TCRs). TCRs indicate the rate at which the resistance changes with temperature. A high TCR value implies a significant resistance change with temperature, affecting the accuracy of current measurements. Evaluating a resistor's temperature drift characteristics allows engineers to select resistors that offer stable and predictable performance across temperature ranges.

3. Mitigating Thermal Effects and Temperature Drift:

To minimize the impact of thermal effects and temperature drift, several strategies can be employed:

a. Thermal Design: Proper thermal management is essential to dissipate heat generated by the Current Shunt Resistor effectively. This can be achieved by using heat sinks, thermal pads, or cooling fans to maintain the resistor's temperature within an acceptable range.

b. Material Selection: Choosing resistive materials with low TCR values can minimize temperature drift. Metal alloys such as Manganin or Constantan are commonly used in Current Shunt Resistors due to their low TCR values, providing stable resistance across temperature variations.

c. Calibration and Compensation: Calibration against a known current source can help account for thermal effects and temperature drift. By periodically calibrating the Current Shunt Resistor, any deviation caused by temperature variations can be compensated for, ensuring accurate current measurements.

d. Temperature Compensation Circuits: Implementing temperature compensation circuits can actively monitor the temperature of the Current Shunt Resistor and adjust the measurement accordingly. This approach minimizes the impact of temperature variations on the accuracy of current measurements.

Conclusion:

Considering the thermal effects and temperature drift characteristics of Current Shunt Resistors is crucial for precise and reliable current measurements. By understanding the impact of these factors and employing strategies such as proper thermal design, material selection, calibration, and compensation techniques, engineers can mitigate the influence of thermal effects and temperature drift, ensuring accurate and consistent current measurements in various operating conditions.