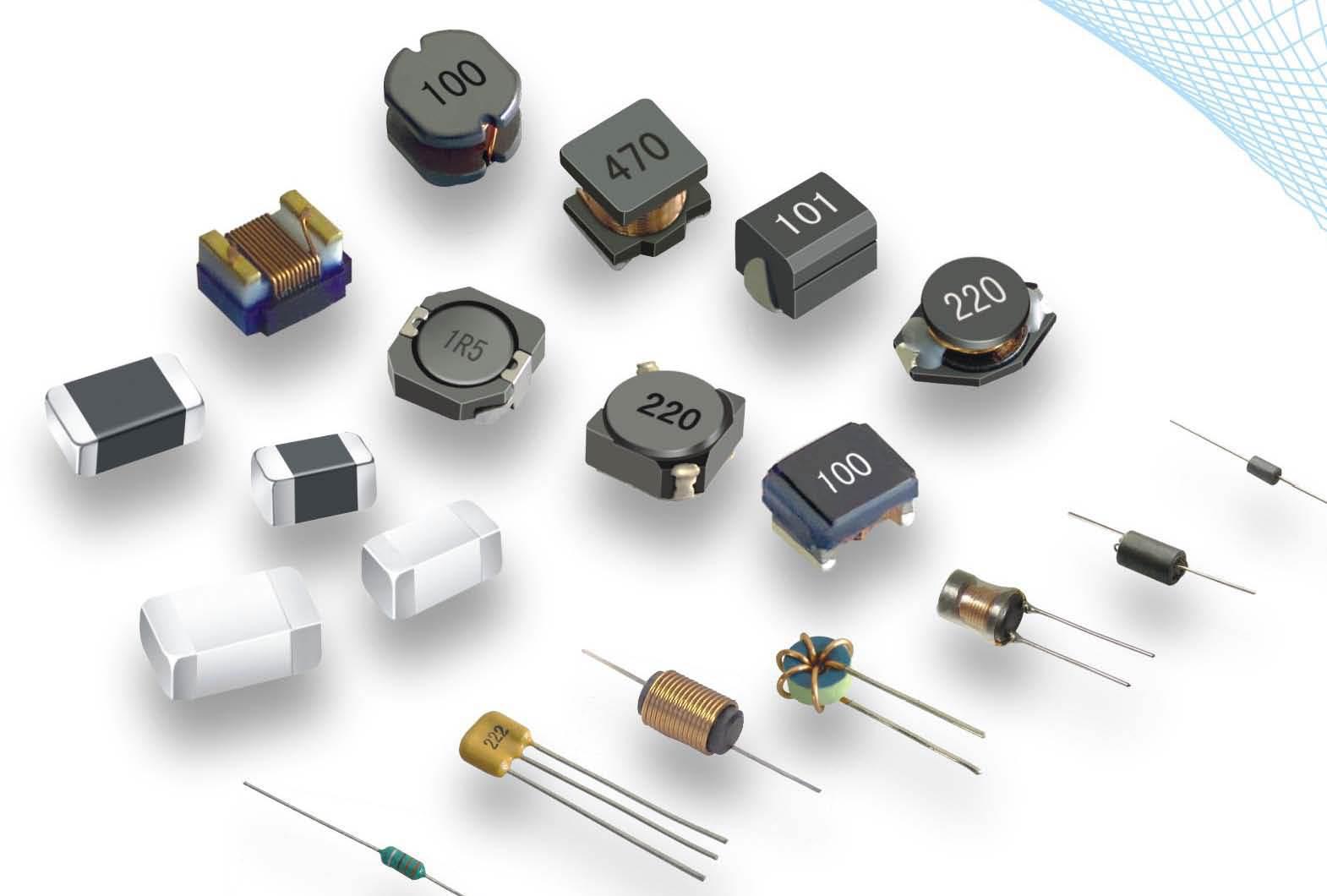

The difference between wire wound inductors and multilayer inductors

The difference between wire wound inductors and multilayer inductors

1. The difference in production process

The wire-wound chip inductor is based on the traditional wire-wound inductor production process, which transforms the plug-in inductor into a chip package, which reduces the volume of the inductor and is more convenient to use.

Multilayer inductors are made using multilayer printing technology and laminated production processes.

2. The difference in performance

Laminated inductors have good magnetic shielding, high sintering density, and good mechanical strength, but the inductance accuracy and inductance range are not as good as wire wound chip inductors.

The outer winding inductor has the advantages of high Q value, low loss, and large current passing.

3. The difference in price: laminated inductors are difficult to produce, technically demanding, and production costs are high, and the price is more expensive than winding inductors.

4. Other differences: the heat dissipation of laminated inductors is better than that of wire wound chip inductors. The laminated inductors cannot see the wire. They are better than wire wound inductors in terms of anti-interference ability, heat dissipation and saving installation space.

Winding inductors are slightly better in terms of current resistance and inductor production cost, and the winding inductance has a higher ESR value than the multilayer inductor.