COB LCD (Chip-on-Board Liquid Crystal Display)

COB LCD (Chip-on-Board Liquid Crystal Display)

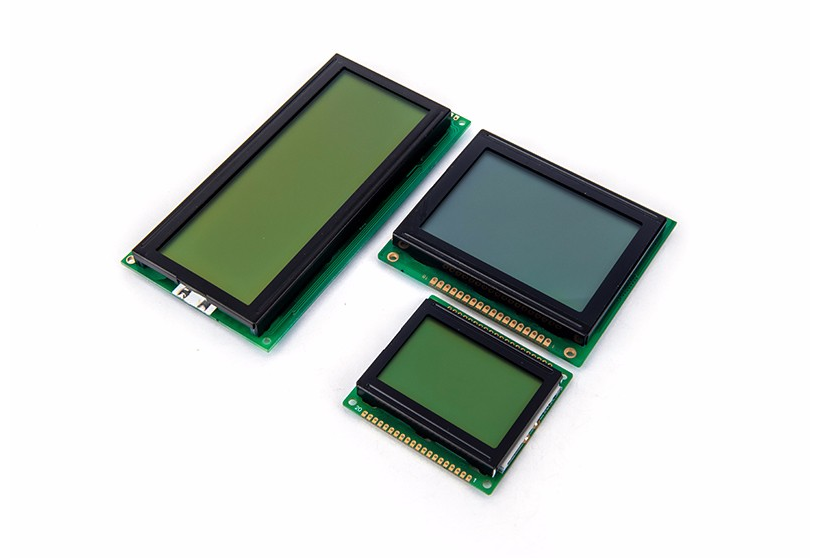

COB LCDs represent a highly integrated display technology where the driver integrated circuits (ICs) are directly mounted and wire-bonded onto the printed circuit board (PCB) behind the liquid crystal layer. This architecture eliminates the need for a separate controller board or external connectors, resulting in an ultra-compact, lightweight, and cost-effective solution. The monolithic design enhances durability by reducing interconnection points, making it resistant to vibration and environmental stressors. These displays typically feature monochrome segments or dot-matrix graphics with high-contrast ratios (e.g., 1:8 to 1:10) and wide viewing angles (up to 120°). Their low power consumption (often <1mW) and compatibility with simple microcontroller interfaces (e.g., SPI, I2C) make them ideal for battery-operated devices.

Key Features & Advantages

Space-Efficient Design:

The elimination of external driver boards reduces total thickness to <3mm, enabling integration into slim-profile devices.

Custom-shaped PCBs allow irregular outlines (e.g., circular, oval) for aesthetic flexibility.

Enhanced Reliability:

Direct chip bonding minimizes solder joints, increasing mean time between failures (MTBF) to **>100,000 hours**.

Operating temperature range of -30°C to +80°C suits harsh environments (e.g., industrial settings).

Cost Optimization:

Fewer components and simplified assembly cut manufacturing costs by 30–40% versus conventional LCD modules.

No need for expensive connectors or flex cables.

Optical Performance:

Standard colors: Yellow-green, blue, or gray displays with LED backlighting options (3.3V drive).

Resolution: Customizable segments or graphic arrays (e.g., 128x64 pixels).

Application Scenarios

Consumer Electronics:

Digital Clocks & Timers: Low-power, always-on displays for bedside alarms and kitchen appliances.

Home Appliances: Status indicators in washing machines (cycle progress), microwaves (countdown timers), and air conditioners (temperature readouts).

Industrial Equipment:

Control Panels: Parameter displays for CNC machines, PLC interfaces, and hydraulic systems.

Portable Instruments: Multimeters, tachometers, and pressure gauges requiring rugged, sunlight-readable screens.

Medical Devices:

Diagnostic Tools: Glucose meters, thermometers, and blood pressure monitors benefiting from EMI-resistant design.

Wearable Health Monitors: Compact size ideal for pulse oximeters or ECG patches.

Automotive & Transportation:

Aftermarket Dash Displays: Fuel efficiency readouts, tire pressure monitoring systems (TPMS).

Public Transit: Stopwatch timers in bus ticketing machines or metro station signage.

IoT & Smart Devices:

Sensor Nodes: Humidity/temperature displays in smart agriculture systems.

Smart Home Controllers: Thermostat interfaces or security panel status indicators.

Toys and Education:

Educational Kits: Electronic quiz boards or robotics controllers with simple graphics.

Gadgets: Handheld games and DIY electronics projects leveraging easy MCU integration.

Technical Specifications

| Parameter | Specification |

|---|---|

| Display Type | Monochrome STN/LCD |

| Interface | 4-bit parallel, SPI, or I2C |

| Supply Voltage | 3.3V or 5V (±0.25V tolerance) |

| Current Consumption | <50μA (standby), <2mA (active) |

| Customization | Segments, icons, or graphics |

Why Choose COB LCD?

Design Freedom: Tailor glass size, PCB shape, and segment patterns to match product ergonomics.

Supply Chain Simplicity: Single-component sourcing reduces logistics overhead.

Global Compliance: Meets RoHS, REACH, and ISO 9001 standards for international deployments.

Conclusion: COB LCDs bridge the gap between basic segment LCDs and complex TFTs, offering a balanced mix of affordability, reliability, and adaptability. Their seamless integration into space-constrained and cost-sensitive applications makes them a cornerstone of everyday electronics. For optical bonding options (enhancing contrast in sunlight) or touch overlay integrations, consult factory engineers.