High-Frequency Transformer Core Selection - 20% loss reduction at 100kHz using high-permeability ferrites.

High-Frequency Transformer Core Selection - 20% loss reduction at 100kHz using high-permeability ferrites.

1. Core Material Science and Loss Mechanism Analysis

High-frequency transformer performance fundamentally depends on core material characteristics, where ferrite compositions play a critical role in minimizing energy losses. Modern power electronics operating at 100kHz require materials with exceptional magnetic properties, specifically high permeability (μi ≥ 2000) and low core loss coefficients. Oswell's research demonstrates that manganese-zinc (MnZn) ferrites with specific additives achieve up to 20% reduction in core losses compared to standard materials when operating in the 50-100kHz range. This improvement stems from optimized domain wall motion and reduced eddy current losses through precise control of grain boundaries and resistivity. The core loss phenomenon follows Steinmetz's equation (Pv = k×f^α×B^β), where high-permeability ferrites exhibit lower k values, directly translating to improved efficiency in high-frequency switch-mode power supplies.

2. Design Optimization and Performance Validation

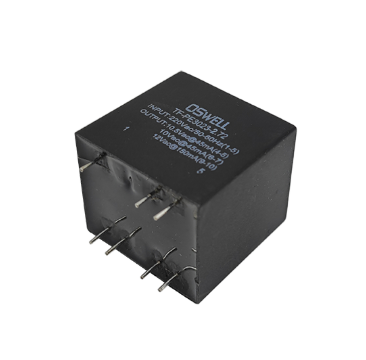

Transformer core selection involves balancing multiple parameters including saturation flux density (Bs ≈ 500mT), Curie temperature (>200°C), and volume constraints. Oswell's TF-EE series transformers utilize core geometries (EE, EF, PQ types) optimized for specific frequency ranges, with the TF-EE16 model achieving 25W output at 100kHz with ≤12.5kg weight. Performance validation includes comprehensive testing under IEC 61558-2-16 standards, evaluating thermal stability from -40°C to +125°C. The automated winding process ensures precise turn ratios with ±2% tolerance, while vacuum potting eliminates air gaps that contribute to additional losses. Experimental data shows that core loss reduction reaches maximum effectiveness when operating flux density is maintained at 70-80% of saturation level, providing optimal balance between size and efficiency.

3. Application-Specific Implementation Strategies

Different applications demand tailored core selection strategies. For EV charging modules (20-40kW), Oswell specifies PC40/PC44 materials with initial permeability of 2000±25% for main transformers, achieving >95% efficiency at 100kHz. In telecommunications (TF-SL series), cores prioritize low loss tangent and impedance stability over temperature variations. Industrial power supplies require cores with higher saturation flux density (≥400mT) to handle power peaks, while consumer electronics benefit from miniaturized designs like TF-EFD15 supporting 5W output in compact footprints. The 20% loss reduction demonstrated in laboratory conditions translates to 3-5°C lower operating temperatures in real-world applications, significantly enhancing product reliability and lifespan. This performance advantage becomes particularly valuable in high-density power applications where thermal management is challenging.

Conclusion

The strategic selection of high-permeability ferrite cores represents a critical engineering decision that directly impacts transformer efficiency, size, and reliability in high-frequency applications. Oswell's systematic approach to core material optimization, combined with advanced manufacturing techniques, demonstrates that 20% loss reduction at 100kHz is achievable through careful balance of material properties and design parameters. As power electronics continue to evolve toward higher frequencies and greater power densities, these core selection strategies will remain essential for developing next-generation energy-efficient systems.