power relay has the following precautions in use

1 When choosing a relay with QC lead-out method, please do not use soldering to connect the load lead-out end of the relay. If other welding methods are used, it is also necessary to ensure that the heat generated by welding will not affect the function of the magnetic latching relay; if there is welding If necessary, you can contact our company to provide welding services.

2 When using the PCB lead-out relay, the recommended soldering temperature and time are: 240°C~260°C, 2s~5s; please do not use reflow soldering, if you really have requirements, please contact our technical staff; Generally, the soldering temperature of wave soldering should not exceed 2s at 250℃; the following figure shows the wave soldering temperature distribution recommended by our company.

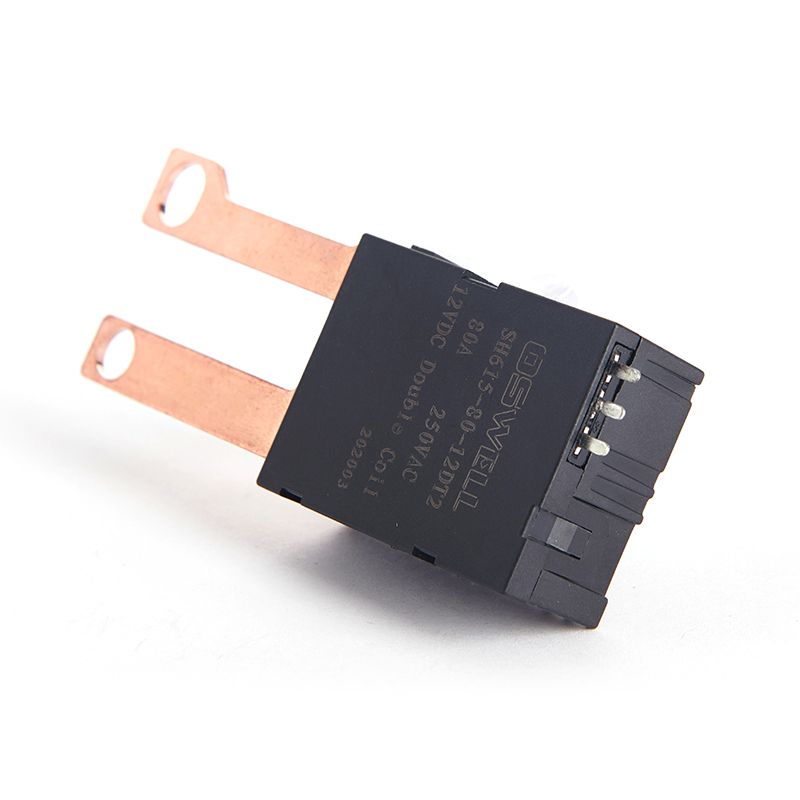

3 When the selected magnetic latching relay is hard-connected, please avoid applying extra stress to the load terminal during or after the installation of the relay.

4 When the selected magnetic latching relay is used to connect the load terminal with screws or bolts, please be sure to tighten the connection to prevent the relay from being damaged or other safety accidents due to excessive temperature rise.

5 The strength of the sampling signal line of the coil (or shunt plate, etc.) is limited. During the installation process, the sampling signal line should be prevented from being twisted or pulled, so as not to cause the sampling signal line to break.

Precautions for the selection of magnetic latching relays for electric meter applications

2.1 Different power companies and meter manufacturers have huge differences in relay requirements. In order to make the magnetic latching relay more reliable in the actual use environment, please inform the technical input that must be determined.