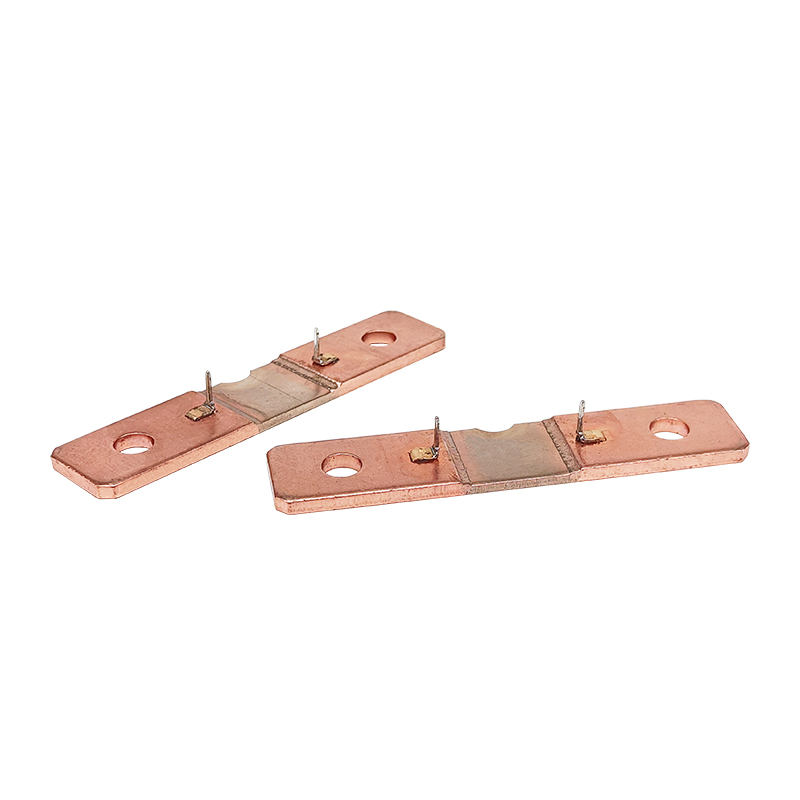

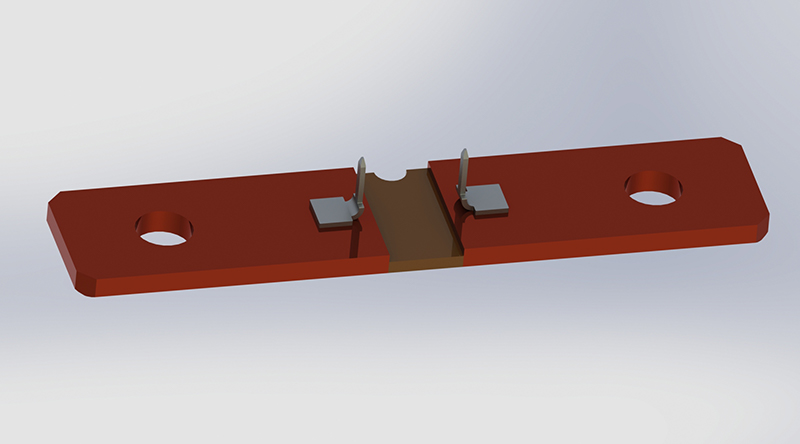

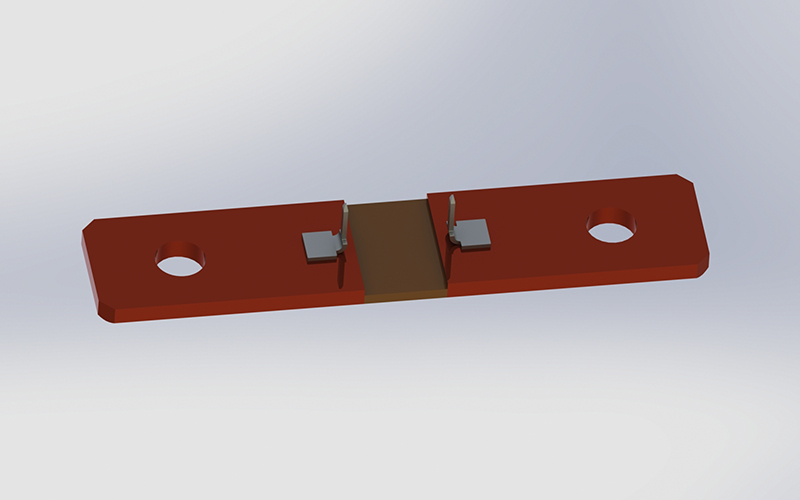

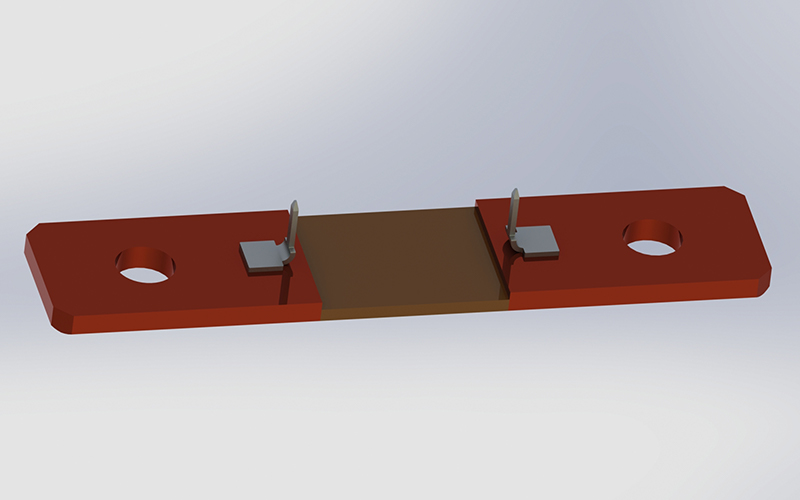

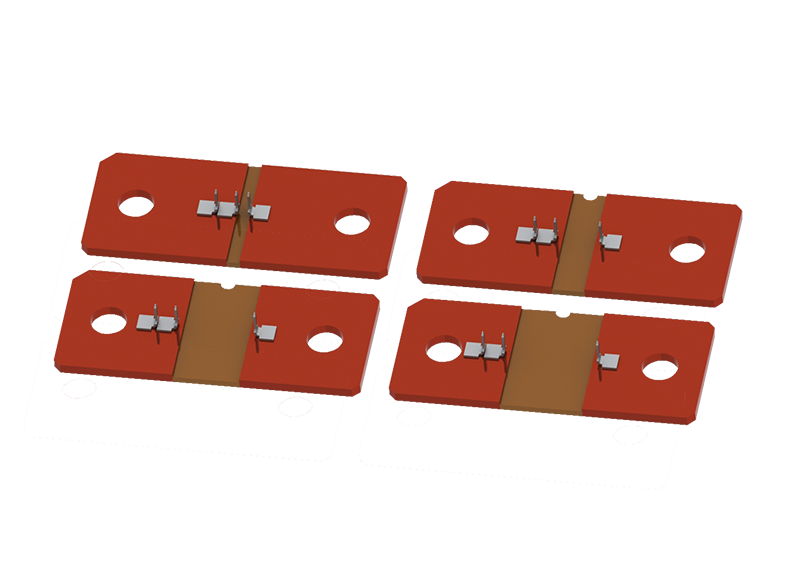

Battery Shunt Resistor SE8518-01/11 With Two Sense Pins

- OSWELL

- CHINA

Big current shunt is made by using excellent stability of high quality manganese copper alloy through a special welding process, can make the shunt in a large temperature change resistance value is still stable.

High precision, low thermoelectric potential, low temperature wave, low power coefficient.

Suitable for power battery pack, high power charging device, power electronic equipment current detection, frequency converter, UPS, motor control and electronic load equipment.

This series is used to instead of Vishay WSBS8518-20/60

Features:

Shunt resistance,shunt resistor current measurement,current shunt,current sensing shunt.

Temperature Coefficient≤150ppm/℃

Comply With EU ROHS Standards

Special Specifications Can Be Customized

According To Requirements

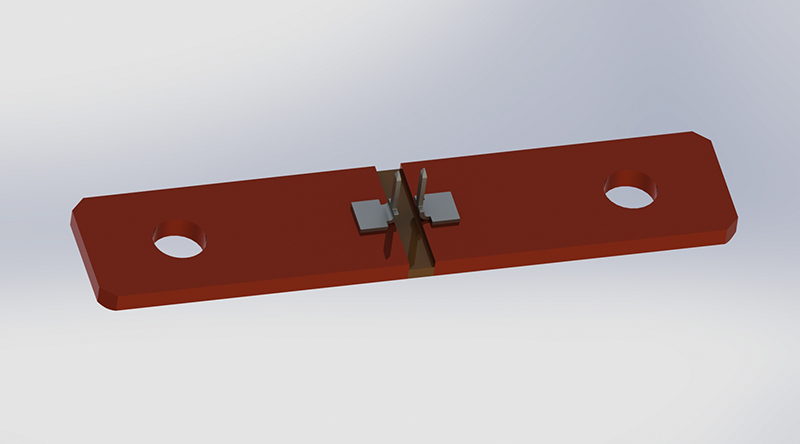

Very Low Inductance <5nH

Electron Beam Welding, Stable Performance

Sustain High Temperature

Tin-Plated (QE8518-60)

Electrical Specifications:

| Model | Size | Power Rating @70℃ | Tolerance ±10% | Resistance Value μΩ | TCR ppm/℃ | Operating Temperature Range ℃ |

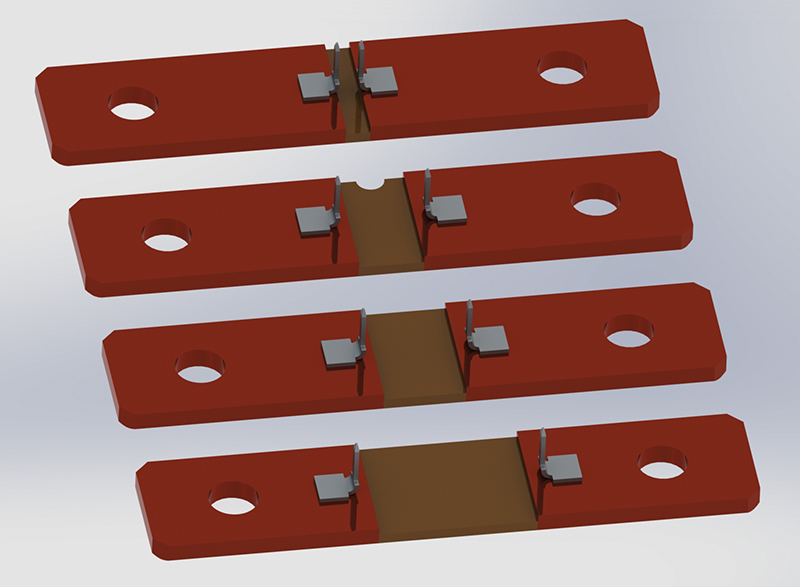

| SE8518-01/11 | 8518 | 36W | 1, 5, 10 | 50, 100, 125, 250 | ≤150 | -55℃~+170℃ |

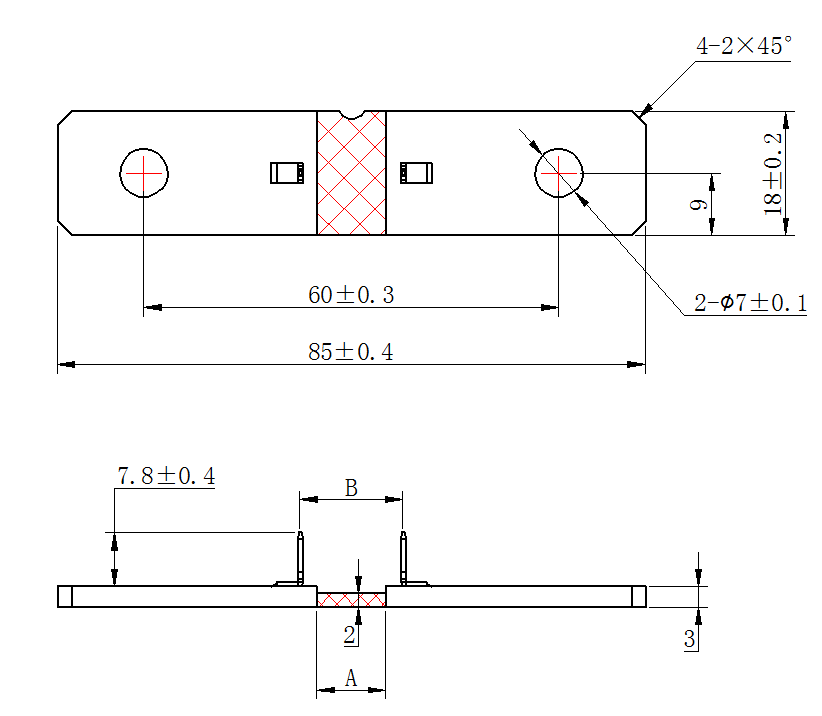

Dimensions: (mm)

| Resistance Value (μΩ) | Element Material | A (mm) Reference | B (±0.2mm) |

| 50 | Mn-Cu | 4 | 3.4 |

| 100 | Mn-Cu | 8 | 12.6 |

| 125 | Mn-Cu | 10 | 14.9 |

| 250 | Mn-Cu | 20 | 26.1 |

Performance:

Test | Specification | Test Methods |

TCR | Within specified | 20℃-120℃ |

Short Time Overload | No mechanical damage △R≤±1.0%R | 5RP for 5s |

Resistance to Soldering Heat | No mechanical damage △R≤±1.0%R | Lead-free solder bath at 260℃±5℃ for 10s±1s. |

Endurance at 70℃ | No mechanical damage △R≤±1.0%R | 70℃±2℃,1000h,Rated current or limiting element current whichever is lower 1.5h ON/0.5h OFF |

Biased Humidity | No mechanical damage △R≤±1.0%R | 85℃/85%RH.1000 hours, Apply 10% of operating power (current) or limiting element current whichever is lower. |

Rapid Change of Temperature | No mechanical damage △R≤±1.0%R | -55℃(30min)~normal temperature(5min)~125℃(30min)100cycles |

Endurance at Upper Category Temperature | No mechanical damage △R≤±1.0%R | 170℃±2℃,1000h |

HF Vibration | No mechanical damage △R≤±1.0%R | 10~200Hz, 98m/s², 6H |

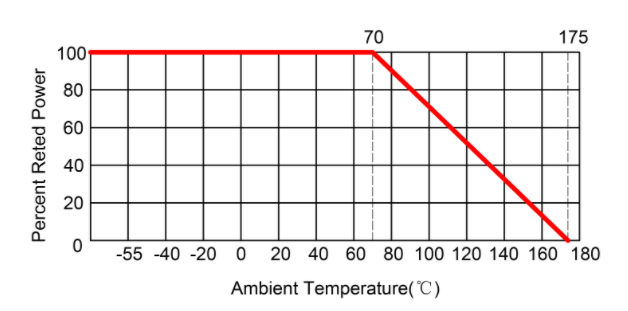

Derating Curve: